Enclosures & Small Vehicle Fire Suppression Systems using BlazeCut Fire Protection

Amet Industries is a distributor of BlazeCut, an Australian Automatic Fire Suppression Systems manufacturer. BlazeCut are specialists that deliver the latest in fire protection technologies. We provide top performing systems, manufactured to the highest quality, that can perform and protect you and your valuable assets in harsh high-risk environments. All the systems are designed specifically for an application to protect all types of equipment and fixed plant.

The BlazeCut systems are not to replace extinguishers, but to supplement and be a first line of fire defence.

Small enclosures

BlazeCut T

(tube) Series

Family Automobiles, 4WD Offroad Vehicles, Marine Boats, Forklifts, Golf Buggies, 3D Printers, Electrical Cabinets, Network & Cabling Installations

large enclosUrEs

BlazeCut C

(cylinder) Series

“Direct Low Pressure” & “Indirect Low Pressure“. Buses & Coaches, Truck & Vans, Construction Vehicles, Mining Vehicles, Agricultural Vehicles, Forestry Machines, Special Army and Police Vehicles, Marine, Electrically Fueled Systems, Electrical Cabinets, Network & Cabling Installations, CNC Machines, Server Racks, Kitchens, Fume Cabinets, Power Generators, Elevator Engines

Available Extras for some BlazeCut Systems:

- Connection to signaling devices or control of external systems (switch-off the ventilation, A/C etc.),

- Activate the system after receiving electronic signal from the external device (for example detector),

- Optional Sounders, beacons, combined optical and acoustic devices

- A Control Panel to control the system, external communication, GSM connection module available.

BlazeCut T (tube) Series

Where is the Agent Stored?

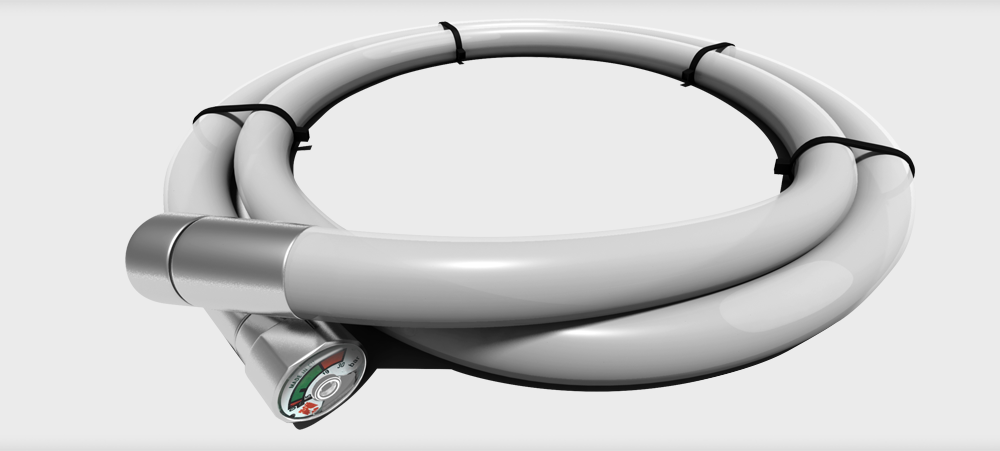

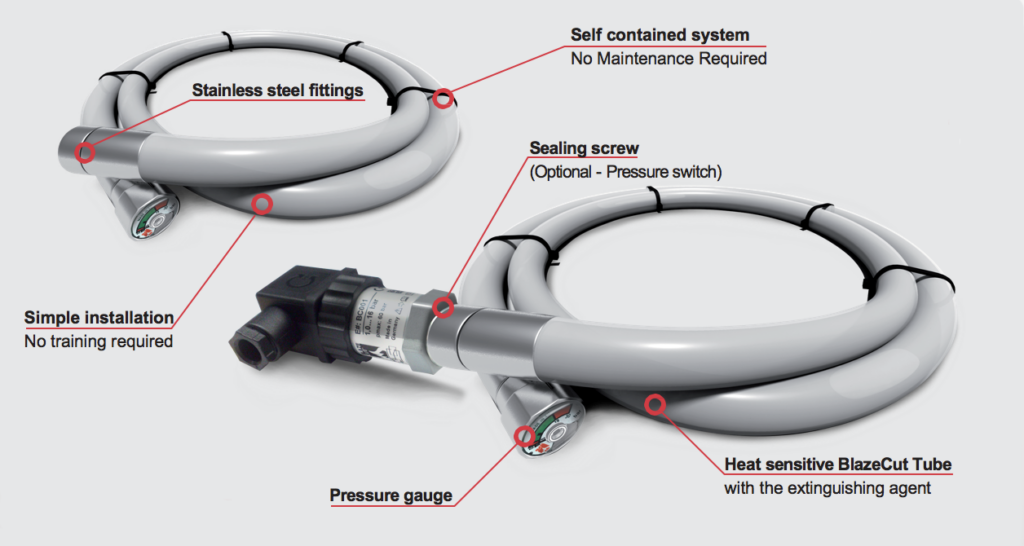

This system consists of a heat sensitive tube, made of special plastic with a closed by a stainless-steel fitting on each end. The tube has both a storage and a detection function. This can be achieved by storing the extinguishing agent in the tube. There are no extra storage devices, such as gas cylinders, that are required.

The “T” (tube) series is a unique product utilizing the best performing material possible. It is not only durable and hard wearing, it also does not split, crack or deform.

When activated

A nozzle shaped opening will be formed above the heat source to assist in the spread of agent through the risk application. No one else has perfected this feature which gives the BlazeCut T series a distinct advantage and an outstanding performance.

Fire Extinguishing Agents

The BlazeCut systems use either Novec 1230, HFC-227ea, HFC-236fa, foam, or powder agents. This is an effective, clean, and people-safe extinguishing medium. These agents have a zero ozone-depleting potential, low global warming potential and a short atmospheric lifetime.

Independent from Power Supply

BlazeCut systems, operate independently from any power supply by detecting higher temperatures. When the enclosure reaches a critical threshold, the detection tube melts at the point where the affecting temperature is the highest. Melting the tube creates a hole, releasing the entire extinguishing agent stored in the tube onto the source of the fire.

Various Tube Lengths

BlazeCut “T” Series systems are supplied in various lengths of the tube and volumes of agent. The standard volume of agent ranges from 0.05 kg to 1.5 kg, which is enough to protect enclosures with volume between 0.09 m³ and 2.73 m³ .

Features

- Type of valve: DLP or ILP

- Type of agent: Novec 1230, HFC-227ea, HFC-236fa, foam, powder

- Volume of cylinder: different volumes depending on type of extinguishing agent

- Dimensions of detection tube

- Wide range of components and installation material: distribution tubing, fittings, connectors, brackets

- Various optional components: pressure switch, control units, signaling devices, actuators, detectors, end of line devices

- Retail box available in 1, 2, 3 and 4 meters size signal and monitoring.

- Compact 19mm diameter tube

- Retail box available in 1, 2, 3 and 4 meters sizes

- Includes pressure gauge, high temperature cable ties for installation, user instruction manual and warning label

- Fast acting with high impact at point of fire

- Normal installation takes 10- 20 minutes

- Hardened tube outer is highly resistant to abrasions.

- Up to a 10-year shelf life is expected and replacement recommended between 5-10 years after installation. All directly dependent on the application environment.

BlazeCut C (cylinder) Series

BlazeCut Fire Suppression C (Cylinder) Series Systems, focusing on Indoor & Closed Compartment Fire Protection.

The C Series fire protection is broken up into two parts,

“Direct Low Pressure (DLP)” and

“Indirect Low Pressure (ILP)”

The system chosen for each application is dependent on the size and type of enclosure.

Larger Enclosed Environments are more suited to use

Indirect Low-Pressure systems.

C Series – DLP (Direct Low Pressure)

Description

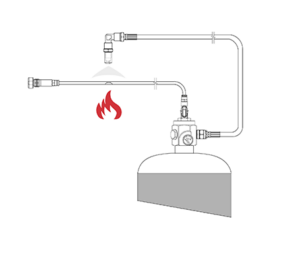

The Direct Low-Pressure system is referred to as direct, meaning that the activation and distribution of the agent is secured by the detection tube.

The fire suppression system operates by detecting a fire and applying the agent using a detection tube fastened to a cylinder valve. The detection tube is installed in the enclosure and is under constant pressure. If fire or high temperature causes the detection tube to be ruptured, the agent is forced through the ruptured tube.

The heat detection system is independent of any electrical supply and operates solely on physical principles. The direct system is suitable for smaller applications and combines easy installation with simple operation.

Benefits

- This is a simple way of applying a gaseous agent from a cylinder on small to medium applications.

- It is a very cost-effective way to protect electrical and fueled applications in fixed or mobile equipment.

- The direct system combines easy installation with simple operation.

- It can be monitored and have external warning devices added.

C Series – ILP (Indirect Low Pressure)

Description

This system is referred to as indirect, meaning that it is activated by the disruption of the detection tube and the agent is distributed via separate distribution tubes to the nozzles.

The vehicle fire suppression system operates by detecting heat with a detection tube connected to a valve of a cylinder. The tube is placed in the protected enclosure and is under constant pressure, whereby keeping the valve piston of the cylinder closed.

Benefits

The indirect system is suitable for small to medium environments or where a specific application of the agent is required. This system also can have various modifications by adding manual actuation, different detection devices, alarm-monitoring panels and external telecommunications and warning devices. All BlazeCut systems use clean agents and are environmentally friendly.

Fire Extinguishing Agents

The BlazeCut Cylinder systems use either Novec 1230, HFC-227ea, HFC-236fa, foam, or powder agents. This is an effective, clean, and people-safe extinguishing medium. These agents have a non ozone-depleting potential, low global warming potential and a short atmospheric lifetime.

Independent from Power Supply

BlazeCut systems, operate independently from any power supply by detecting higher temperatures. When the enclosure reaches a critical temperature threshold, the detection sensors activate the extinguishing materials automatically without the dependency on any external power supply.

Engine Compartments 🔻

Vehicle fires are an issue all over the world and the number of such fires increases each year. Majority of vehicle fires have its source in the engine compartment. The most dangerous sources of fires in the engine compartments include electrical arcing, overloaded wiring, hot surfaces, mechanical sparks, electrical sources.

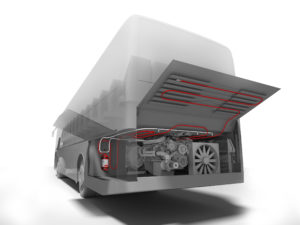

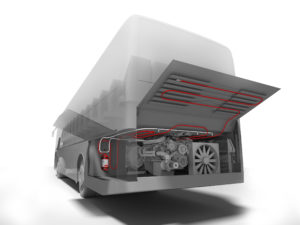

Buses 🔻

Engine compartments of buses are prone to fire. Statistics have shown that a number of factors cause these fires: short circuits, engine wear, hot surfaces, reduced durability of materials, use of plastics, encapsulation of the engine, oil, and debris.

Over 70% of bus fires occur in the engine compartment alone. Buses are used for everyday transport of people. Fire protection of these vehicles should be made top priority for every bus operator and manufacturer.

Statistics*:

- 10% of all buses are involved in a fire incident during their lifespan

- In Germany 350 – 400 bus fires are reported every year

- Bus fires have almost doubled in many countries over the last 10 years

- In the USA an average of six bus or school bus fires are reported every day

- More than 70% of all bus fires occur in the engine compartment

*Source: NFPA and SP Technical Research Institute

BlazeCut provides ILP (Indirect Low Pressure) bus systems that can be adapted and fitted to any type of bus.

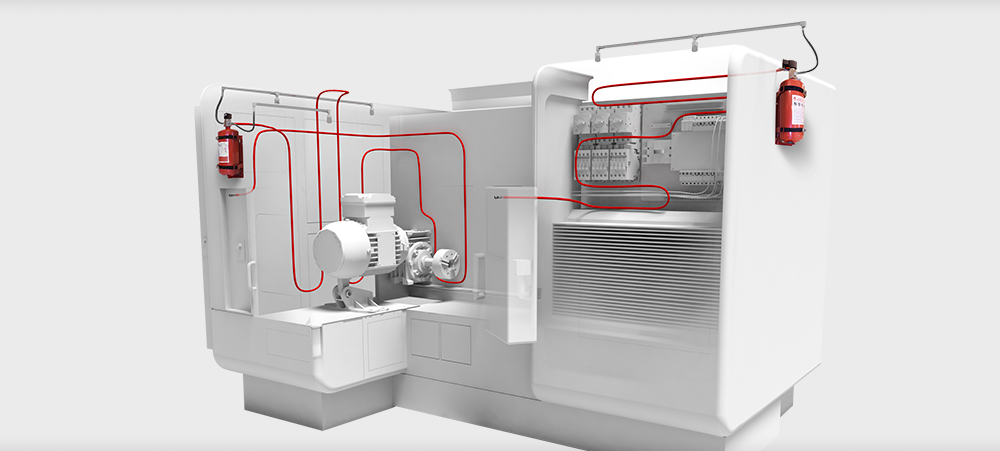

Indoor Applications 🔻

Industries must ensure that their key non-human assets are free of any fire hazards. Server racks, CNC machines, electrical cabinets, power generators, etc., all pose fire risks to people and businesses. Cables and wires in electrical enclosures, chemicals in fume cabinets and machines or oils and fats in kitchens are factors that pose a great risk of fire.

The BlazeCut fire suppression c series, provides automatic fire suppression systems for these kinds of enclosures through its BlazeCut “C” Series local application systems. Depending on type of application, the systems are supplied with Novec 1230 or HFC-227ea extinguishing materials, which are the best choice for protection of electrical enclosures and sensitive devices or with foam extinguishing agent for kitchen applications.

Direct Low Pressure and Indirect Low Pressure for INDOOR Applications 🔻

Direct Low Pressure and Indirect Low-Pressure versions, of the C series BlazeCut System, are both used for indoor applications. These come in various modifications of cylinder sizes, lengths and sizes of detection and distribution tubing.

Optional components for BlazeCut Indoor Applications:

- Optical and smoke detectors for fast detection of fire and activation of the system

- Manual pneumatic actuator independent of electrical power

- Manual electric actuator for electrical activation

- Pressure switch to connect signalization devices or control external systems (switch-off the ventilation, A/C etc.)

- Solenoid switch to activate the system after receiving electronic signal from the external device (for example detector)

- Signaling devices: sounders, beacons, combined optical and acoustic devices

- Control panel to control the system, communication with signalization, GSM module etc.